Fike Battery Hazard Analysis (BHA) Explained

Fike Corporation, a global leader in industrial safety solutions and manufacturer of the first third-party tested solution proven to stop thermal runaway, Fike BlueTM, announced it is now accepting battery and energy storage system manufacturers into the Fike BHA (Battery Hazard Analysis ) Program.

A Fike BHA determines and validates the protection approach using Fike Blue as the thermal management and fire protection solution to protect lithium ion battery assemblies from thermal runaway.

“Because every battery is unique, it’s not enough to simply try to prescribe a ‘one-size-fits all’ thermal management approach,” said Tom Farrell, Manager of Testing and Validation at Fike. “We are focused on devising a solution that fits with the customer’s unique product and their specific hazards in mind.”

The BHA provides ESS manufacturers with confidence that their ESS equipped with Fike Blue will pass UL 9540A certification at a Nationally Recognized Testing Laboratory (NRTL), will meet local AHJ (authorities having jurisdiction) requirements, and most importantly, will keep nearby people and property safe.

This is achieved through…

- Designing a custom ESS thermal management and fire protection solution using Fike Blue that fulfills the demands of the unique application

- Validating the Fike Blue solution in a Unit-Level Test, guided by UL 9540A

- Identifying potential risks within the ESS design that could make suppression of a thermal runaway event difficult (or impossible), as well as identifying risk mitigation solutions

- Producing a thoroughly documented yet easy-to-read BHA Report to submit to AHJs, fire marshals, insurance providers and more

“Fike’s goal in the BHA is to provide ESS design element feedback that will enhance the efficacy of Fike Blue and further increase the probability of success during certification testing through a process that is intended to be fast and cost-effective,” said Farrell. “This enables ESS manufacturers to rapidly iterate their design while demonstrating the effectiveness of a custom, performance-based thermal management and fire protection solution.”

The information provided in the Fike BHA Report includes:

- Section I – Executive Summary – Assessment of the test results through the lens of requirements listed in UL 9540A. This section will have significant value to conversations with AHJs and fire marshals, as well as guidance for next steps in testing, if indicated.

- Section II – Introduction – General overview of the objectives of the test program, the intended use of the ESS under testing and any other pertinent background information. Identified performance risks (excessive venting, leaky cabinets, lack of thermal isolation between cells, etc.) will be discussed, and details regarding the cell manufacturer, cell chemistry, cell voltage and battery assembly part numbers will be documented.

- Section III – Experimental Setup and Validation Approach – Details the test set-up, discusses the measurement equipment used and notes the location of all instrumentation installed within the ESS under test. Any modifications to the ESS module under testing (necessary for instrumentation and/or to address possible risks to efficacy of Blue) will also be noted and documented thoroughly. Upon successful test results, system design that would be applied in the field will also be provided.

- Section IV – Results and Discussion – Documents the approximate two hours of test results: heating (typically 1 hour), thermal runaway and fire (typically 5 to 30 minutes), and thermal equalization after the last cell undergoes thermal runaway (typically 1 hour). A discussion of the efficacy of Blue™ in the current ESS configuration, recommendations for ESS modifications to enhance the efficacy of Blue™ (if necessary), recommendations for additional testing, analysis of collected data and an overall assessment of the performance of the protective system will be provided.

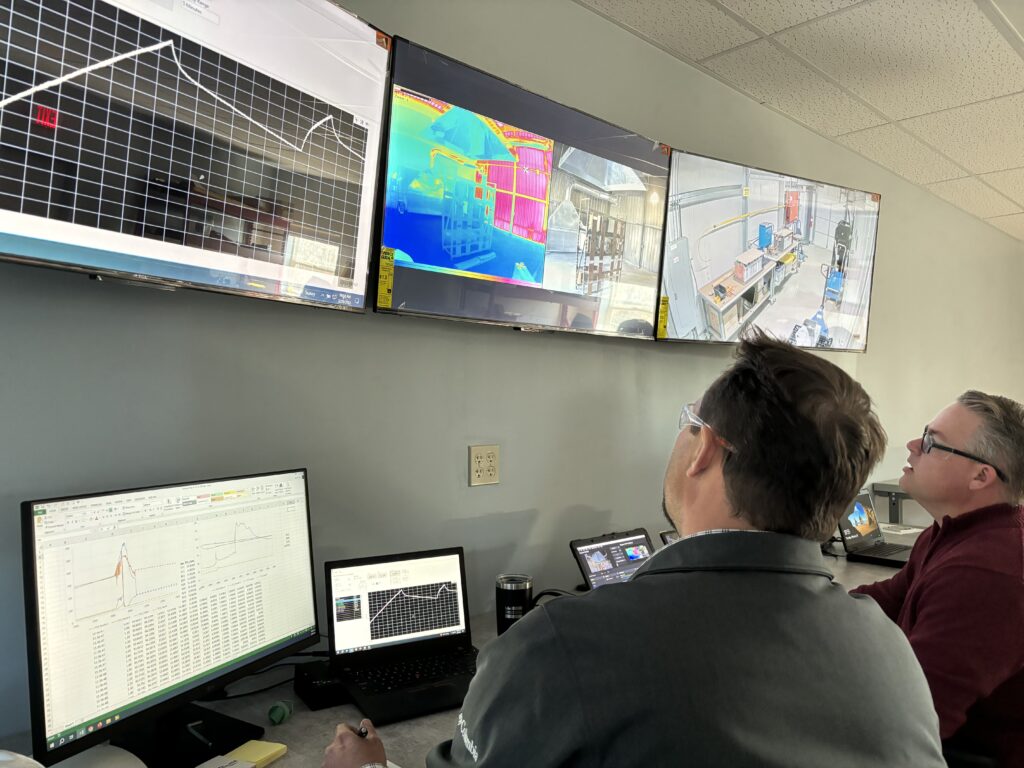

Fike BHAs are conducted at Fike’s world headquarters in Blue Springs, Missouri, where testing and analysis may be observed in person or virtually from anywhere in the world.

“The customer is very involved in this process, right down to being involved in the testing itself,” Farrell said. “If they are interested, we bring them in, and they get to witness all the steps of the BHA. They’re part of the analysis as we go through it, and even through the delivery of the test report, they get to review all that information and have intimate access with the experts inside Fike.”

Contact the Fike team today to learn more about ESS testing and validation.