Navigating the Future of Energy Storage Safety:

Q&A with Tom Farrell on Conquering Thermal Runaway Propagation

We recently interviewed Tom Farrell, Principal Engineer of Test and Validation Engineering at Fike Corporation about the dangers of thermal runaway, the solutions currently used to mitigate its effects, the effectiveness of Fike’s solution Fike Blue, and more about the advancement of safety in the energy storage industry.

Q. Why aren’t energy storage systems used more often in populated areas?

Obviously, these batteries burn. We know they burn. They catch fire when they’ve been abused or when a defective cell begins thermal runaway inside of a module.

Early on when we had these fires, the first thought was to treat it like a fire by using Class B sizing and protective methodologies and prove the results with small-scale testing. A lot of organizations offered testing advice based on this kind of approach; however, it hasn’t worked out terribly well because a number of notable events have occurred.

Specifically looking at the unfortunate event in Surprise, AZ, protective systems were in place that were supposed to stop what we considered to be a fire. Yet, these fires continued to burn and go for quite some time, releasing enormous amounts of toxic and explosive gases and thermal load to other adjacent structures, and it’s extremely problematic.

The question is, did the fire protection system put out the fire? Arguably, yes. It triggered, reduced the initial heat and diffused flames that were being generated from those batteries.

“But when you look at pictures from the event in Surprise, does it look like it was suppressed? No, because it didn’t address the real problem, the problem of propagating thermal runaway. It’s extremely dangerous and unpredictable, and traditional fire suppression systems simply don’t solve the issue.”

Because there hasn’t been a reliable solution to cascading thermal runaway, AHJs are cautious to allow ESS’s into their jurisdictions and are one of the primary reasons why ESS’s are usually isolated to remote locations.

Q. Do ESS owners and operators generally believe they are protected from thermal runaway?

In the current state of the market, there are a lot of disclaimers that protective system manufacturers will provide in their quotes that say yes, we will absolutely deal with your fire hazard. Oftentimes, that satisfies the fears of ESS owners.

However, the fire protection manufacturers know that there is a thermal management problem in the background that they aren’t going to touch.

Again, the fire can be put out with a lot of traditional means: chemical agents, water, water mist and inert gases, but that threat is still there. You still have a real thermal management problem. Because a lot of those systems discharge and deplete, the next time a cell goes off and generates more toxic gases, it pushes the protective gases out of the system, and you no longer have any protection at all within that module.

This leads to a situation where we need a solution that’s not just a fire protection solution but also a thermal management solution to deal with this threat of cascading thermal runaway. Far too many owners of ESS’s are unaware of this issue, as they believe they are protected.

Q. Can you tell us about Fike’s current testing capabilities and any notable initial takeaways when testing these batteries?

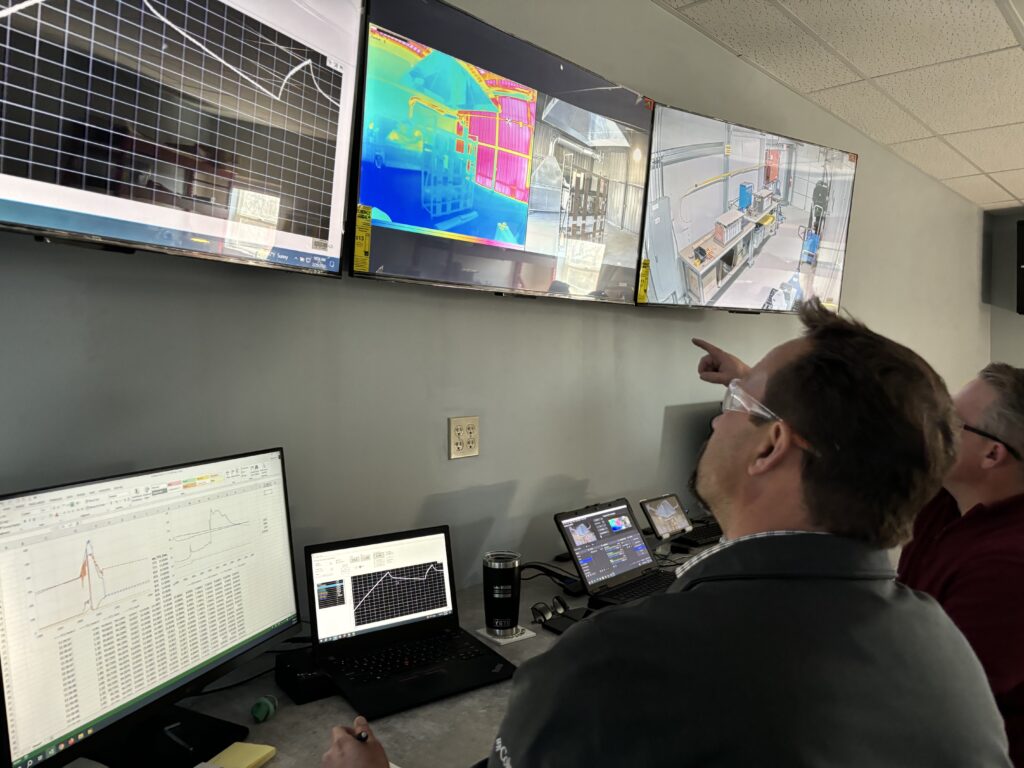

Fike’s Innovation and Testing Center located in Blue Springs, Mo., just outside of Kansas City, focuses on unit- and installation-level testing, so we aren’t just dealing with cells, but we are also dealing with modules and racks of modules. We take a lot of measurements on temperatures, heat flux, thermal load and much more, and we have high-speed cameras and thermal imagery to visualize the data. Offgas testing is still under development but will be deployed in the coming months. It’s basically a UL 9540A test without the gas sampling. We can test a variety of battery types, and this facility is where we’ve done the vast majority of our R&D work to date.

After several weeks of initial testing with a customer’s lithium ion batteries, the end result was a lot of frustration because we were just confirming to ourselves the theory that everyone else was believing: thermal runaway cannot be stopped.

We did an initial module test and all we did was let it burn and set into thermal runaway. There was an extreme amount of smoke generated. We had a ventilator running at about 20,000 CFM to extract that, and even still our test cells were completely filled with smoke and overwhelmed with gas generation, which is another reason these ESS’s can’t be deployed near populated areas because that gas is toxic and there’s a lot of it.

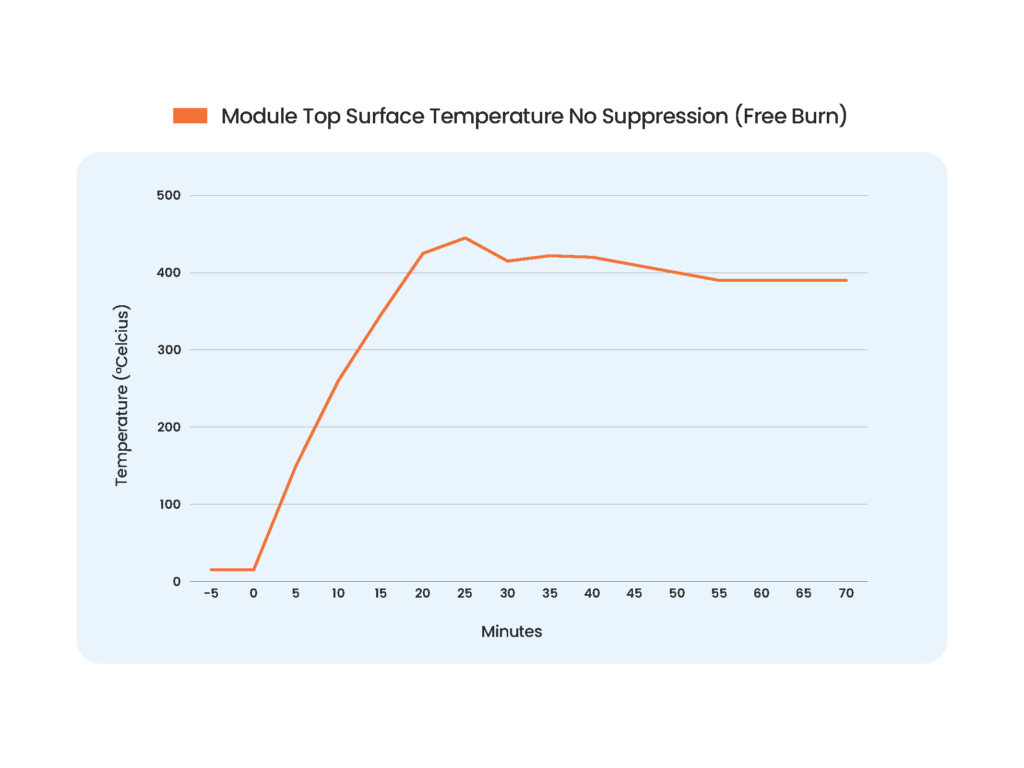

This test was also characterized with extremely high temperatures on the surface of the module itself. As you can see (Figure 1), about 450 degrees celsius of the skin, and anything nearby is also receiving that heat. There’s nothing anyone can do with this until it cools down. At the conclusion of this test, it took about 18 hours for the skin to come back down below 100 degrees celsius. So it takes a long time, especially when you think about the thermal load on structures nearby or the ability for first responders to enter. They can’t do it. It’s just too hot.

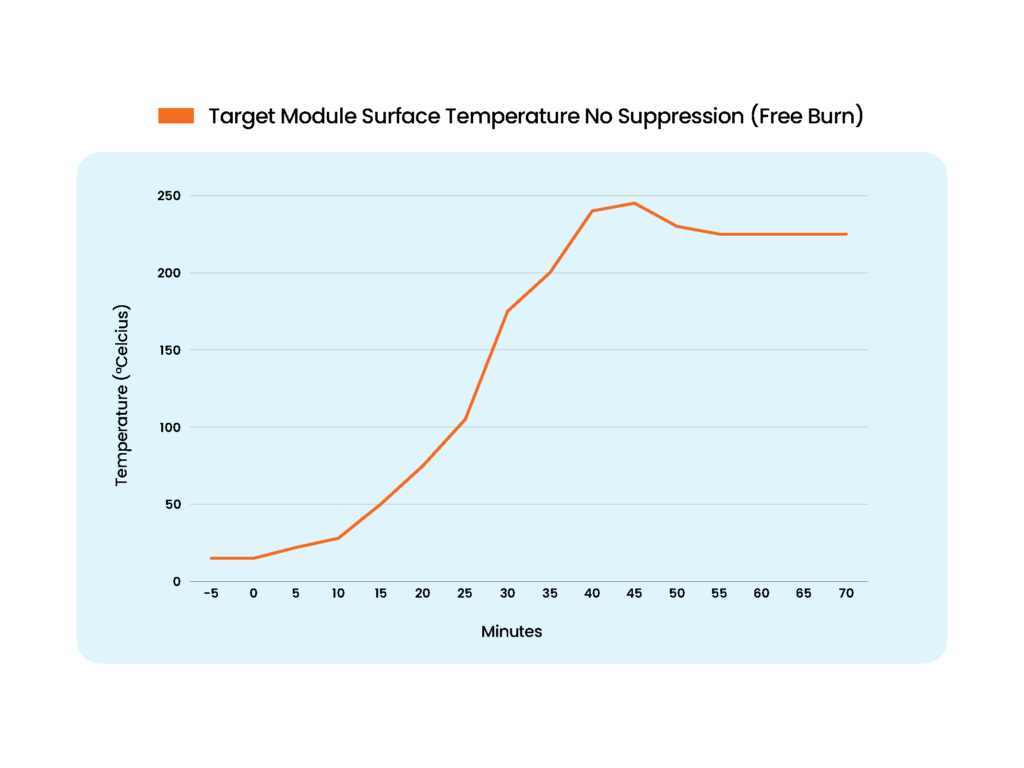

Figure 2

We had a module directly above our “target module,” and the temperatures were also extreme and reached about 250 degree celsius (Figure 2). If you’ve done any testing with these batteries, you know at 250 degree celsius your battery is already going into thermal runaway if you subject it to those temperatures. You’re a long way into that, which means you’ve already set the next module off and it will keep going and going.

There’s nothing to stop this cascading reaction, until we finally found the solution. And that would ultimately be named Fike Blue, an agent that showed promising results to not only suppress a fire like your typical fire protection system but also had the added benefit of stopping cascading thermal runaway at the module level.

Q. Did you attempt using Fike Blue in this series of testing, and if so, what were the results?

We decided to apply this new solution to those same batteries.

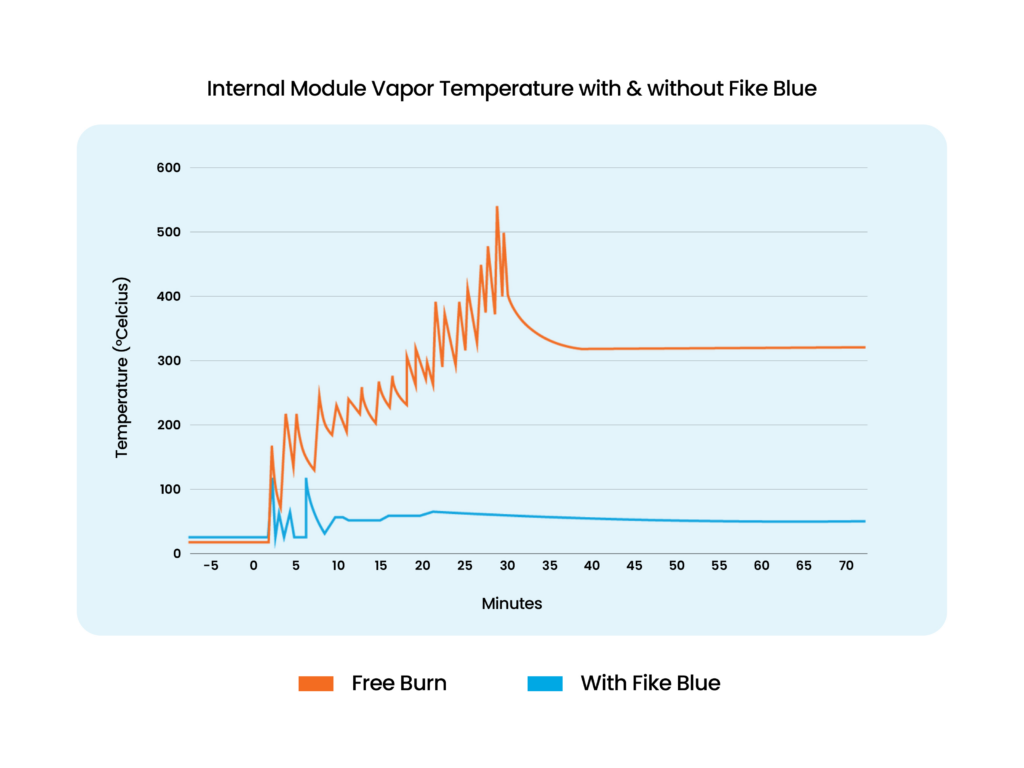

In the test, we only lost six of the 36 cells. The ones that were lost were two groupings of three cells: one with the heater applied and the one on the immediate other side. Everything else in the case was unharmed and it drastically reduced the thermal output and offgas that came off the system all the way down to about 60-70 degrees celsius (Figure 3), a far cry from 450 degree celsius in the “let it burn scenario” in the very beginning.

These are extremely low temperatures for these kinds of fires, low enough where immediately after an event that first responders and utility personnel can enter and extract that module that is having the issue using typical PPE. It did still generate some offgas, but it reduced the gas generated by 36 cells to six cells, assisting in the ventilation system’s job to dilute and diffuse it. This means that if you’ve reduced those toxic emissions, you can bring these systems much closer to populated zones.

And if you look at the temperature of the module above the test module, it barely even heated to just 19 degree celsius.

Q. Can you speak more about the heat absorbed by surrounding modules?

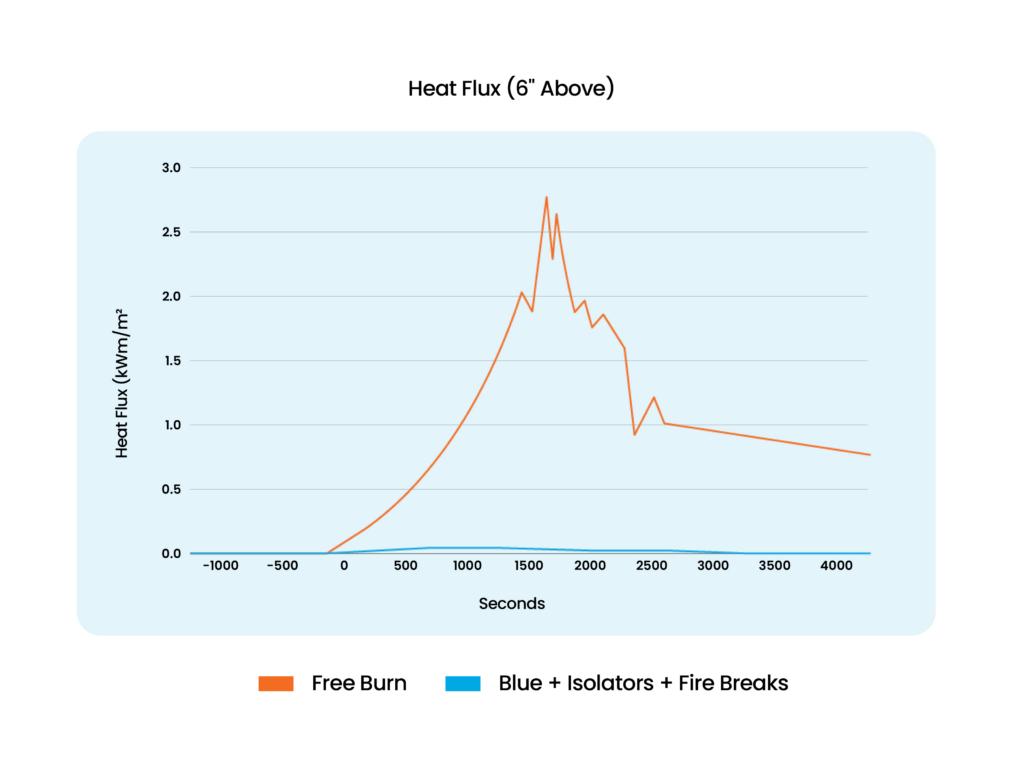

The heat flux being generated off of these is extremely important because it goes back to the discussion of keeping first responders safe, allowing them to enter and do their jobs safely. The standards say that you can’t exceed about 1.3 kw/m2 out to the center of your occupied space, so we went ahead and measured the heat flux at six inches.

During the free burn test, we were up to around 2.5 kw/m2, but with Blue applied it almost didn’t register (Figure 4). This means a couple of things: protection for first responders, and a whole lot less heat imparted to additional modules that are above, to the sides and below inside of a rack configuration. And that means less likely for continued propagation into other models.

Q. Was this the only testing you’ve performed for Fike Blue?

Not at all. For example, we also performed this test at CSA, a nationally recognized test lab (NTRL) with a full rack of batteries (Figure 5). We used the same setups, and the event was over in about five minutes. The experts that were there had commented they had never seen this done before, and we’ve done it several times now in front of those experts. They are unaware of any agent that was able to successfully stop thermal runaway inside of a module.

Q. Why does Fike Blue work so effectively to suppress the propagation of thermal runaway?

Fike Blue is a liquid, directly injected into the module and intended to manage the thermal event by absorbing the heat. It has a very high boiling point, much higher than water, which helps it stick around for a long time and keep doing its job. It doesn’t dissipate like gases would in a typical fire suppression system.

In the testing we ran, only used about 26 gallons of Fike Blue as opposed to the thousands of water that would be required with traditional sprinkler systems or from a fire hose. It’s not very electrically conductive, so it doesn’t cause any cells to also go into thermal runaway like water has the ability to. Also, it’s completely non-toxic, biodegradable, and because you use so much less of it, the concerns about contaminating groundwater or having a massive EPA issue is significantly less.

Q. Knowing what you know now, what is your opinion on the “let it burn” strategy for ESS’s?

The “let it burn” philosophy is one I find to be irresponsible at best and dangerous in typical scenarios for two main reasons. One, is the incredible thermal load you subject other structures to and other batteries to, and the other being the immediate danger to the environment and life in occupied spaces. If you let a battery burn, you generate fire obviously but also an enormous amount of toxic gases. Letting it burn takes care of the flammable gases just fine if things are on fire, but all those toxic gases have to go somewhere. If you have 1000 cells inside a battery, and you let all those burn, you generate 1000 cells worth of toxic gas that is going into occupied spaces and render them unoccupiable for some time.

If this is in an urban setting, this can have disastrous consequences. If you’re able to suppress it and stop propagating thermal runaway, instead of losing 1000 cells, you may only lose 50, which means that can be dispersed and get to levels which are not quite so toxic to people in the immediate vicinity.

Fike Blue opens up a very real possibility that ESS’s may be safely deployed into various urban environments. In our opinion, this makes the let it burn strategy adopted by various industry professionals and decision makers one that is non-sustainable and ultimately unsafe, particularly when a better solution like Fike Blue exists.

This offgassing will cause hazards especially for those in populated areas, so there’s a vested interest in minimizing what comes off of that. The agent also has other additives that will absorb things like HF, so you are reducing those other hazards, and just by cooling everything down you are generating less gas.