Why Consensus on Energy Storage System Protection is Needed Now

Battery fires within energy storage systems (ESS’s) aren’t as rare as one might think.

The reason they are often underpublicized and, fortunately, there haven’t been more tragedies (such as the four critically injured firefighters in Surprise, AZ in 2019), is because ESS’s are often installed away from residential or commercial areas.

However, with the ongoing adoption of renewable energy production, in addition to electric vehicles, microgrids and other green energy solutions, ESS’s will no longer be isolated to solar farms located in the desert or wind farms located in “fly-over” country, but rather will soon be found almost everywhere you look as they continue to push further into our suburbs and cities.

For example, in the near future EV owners may fuel up at their local grocery store’s fast-charging station, powered by roof-top solar panels and discharged from an ESS.

This is why it is critical for local AHJs (authorities having jurisdiction), fire fighters, city planners and decision makers to adapt to where technology is leading society. They must understand the hazards of ESS’s and be educated on the best methods to protect them from the phenomenon known as “thermal runaway.”

The Ever-Present Threat Of Thermal Runaway

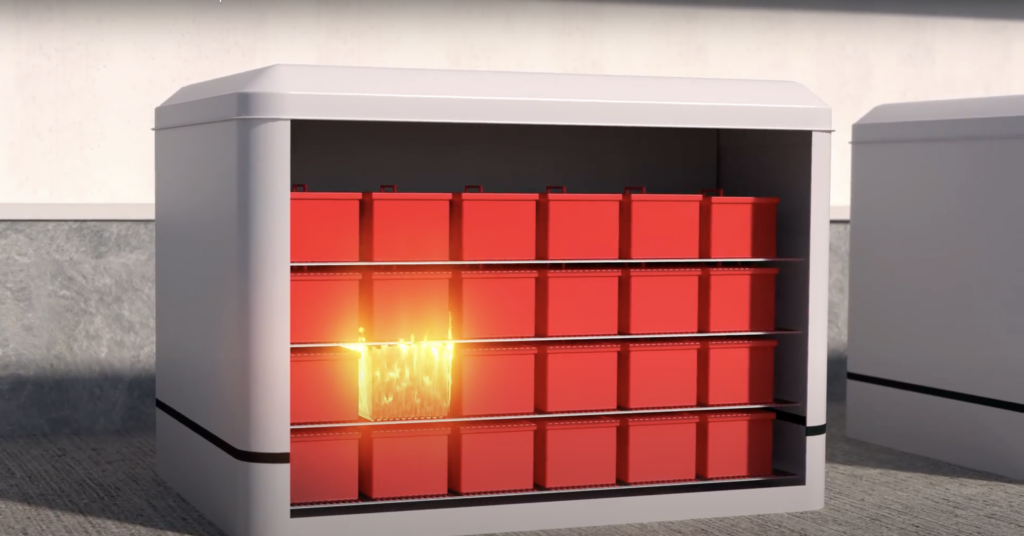

Within an ESS are hundreds to thousands of lithium-ion battery cells, any of which can unpredictably malfunction and go into thermal runaway. During a thermal runaway event, the temperature of the battery increases rapidly, leading to a self-perpetuating cycle of heat generation.

Once a battery experiences thermal runaway, “cascading” thermal runaway is also very likely to occur. Cascading thermal runaway refers to a scenario where thermal runaway propagates from one cell to adjacent cells within a battery module, leading to an uncontrolled release of energy. This process can continue to spread throughout the battery modules, consuming all batteries and potentially resulting in a large-scale fire or explosion.

The stages of cascading thermal runaway include:

1. Exothermic Reaction: Overcharging, short-circuiting, mechanical damage or exposure to high temperatures causes chemical reactions within the battery cell to accelerate, leading to the release of heat. The heat generated rapidly increases the battery temperature.

2. Gas Generation: The high temperatures cause the decomposition of electrolyte components, leading to the release of flammable gases such as hydrogen and carbon monoxide. The gas generation contributes to the increase in pressure within the cell.

3. Venting and Fire: At a certain temperature and pressure threshold, the cell may rupture or vent to release gases. If the released offgas comes into contact with an ignition source, such as a nearby flame or spark, or a flame from the battery itself, it can ignite and result in an even greater fire or explosion.

While NFPA 855 provides guidelines on how best to protect ESS’s, and more importantly, nearby people from the dangers of thermal runaway, there remains ambiguity, uncertainty and differing opinions whether certain solutions actually work. For example, NFPA 855 A.4.11.1 states:

“While non-water-based fire suppression has been shown to be effective at suppressing Class B and Class C fires in ESS enclosures, current suppression agents, both water based and non-water based, are probably not going to be able to stop thermal runaway. No published case studies, test reports, or data generated to date indicate otherwise.”

This unpredictability for when thermal runaway may occur and the dilemma for how best to respond to a thermal runaway event has resulted in many AHJs being hesitant to allow the expansion of ESS’s into their jurisdictions.

IS THERE REALLY NO SOLUTION TO THERMAL RUNAWAY?

Numerous safety solutions providers have attempted to solve this issue of thermal runaway and make ESS’s safe to deploy into more urban environments.

One of those companies is Fike Corporation, best known for its decades of providing fire protection, explosion protection and pressure relief solutions around the globe. The team at Fike’s Testing and Innovation Center in Blue Springs, Mo. began studying thermal runaway in ESS’s and experimenting with various solutions, both ones that are currently being used in ESS protection and others that have yet to be proven ineffective. They found that while NFPA 855 was correct in that water, aerosols and gaseous agents (such as NOVEC 1230) were unable to suppress cascading thermal runaway, there was one solution that showed promise.

After many months of internal testing and third-party testing with CSA (Canadian Standards Association) in 2023, it was obvious that Fike had discovered a solution that actually worked, which they named Fike BlueTM.

“Our experimenting with solutions for thermal runaway began with a lot of early detection and methods of suppressing the fire long enough to get somebody out of harm’s way,” Cedric Johnson, Director of Sales – Americas, said. “However, at Fike, we are builders, engineers and innovators, so we wanted to actually solve the problem. Our research and development team decided to try to figure this out once and for all.

“There was a lot of trial and error. We tried everything on the market that you could think of, and our engineers got a little crazy with it, trying different methods, both old and new technologies, and we came up with Fike Blue. Even some of our initial partners and customers didn’t believe it. We had to do the test 3-5 times to prove it worked. I think the surprise is not that we say it works; the surprise is that we welcome anyone to observe the tests so we can prove it.”

What the Fike team discovered and had proven time after time was an immersible solution that completely fills the battery module experiencing thermal runaway and, with a boiling point of more than 400°C, has the ability to absorb the exothermic heat. Fike Blue doesn’t just slow down the hazard, but actually cools the battery cells and stops thermal runaway from further propagation.

(Test data of Fike Blue observed by CSA in 2023)

HOW DOES FIKE BLUE COMPARE TO OTHER SOLUTIONS OF THERMAL RUNAWAY?

The biggest shortcoming shared between all of the solutions currently used to combat thermal runaway is the high chance of reignition of the battery cells. So even when those solutions are used and may successfully suppress the fire, the chemical reaction within the battery remains ongoing.

That’s not to say that these solutions aren’t still useful for addressing part of the fire hazards within an ESS.

“Within a control room or telecom closet of an energy storage unit, these solutions are extremely effective for stopping Class C fires,” Kevin Montgomery, Manager, Fire Protection said. “However, they do not get to the root cause of the problem of thermal runaway which is a thermal management problem. As a battery cell fails, it could have heated up two or three cells around it, and it could be minutes, hours or even days later that they too could undergo thermal runaway. Additionally, with a gaseous agent for example, you’ve already discharged your initial shot, and now you’re unable to have that when the second or third cell also experiences thermal runaway.”

Another important element to consider about combatting thermal runaway is the effect on the environment. Oftentimes, a compromised ESS will be met by a local fire department whose only option is to discharge countless gallons of water onto the hazard. Harmful chemicals including a mixture of carbon dioxide, hydrogen, ethylene, methane, benzene and more will run into the local environment, groundwater and possibly even nearby bodies of water. Any efforts to protect the environment with green renewable energy production can quickly and unfortunately be undone with one burning ESS treated with fire hoses. Fike Blue helps solve this problem, as manageable amounts of liquid will likely flow from the module onto the floor of the ESS, which can be easily dried with a material such as sawdust, swept up and responsibly disposed of.

Fike Blue isn’t the only contribution Fike is making to improve the safety of the adoption of ESS’s. Fike’s Testing and Innovation Center welcomes ESS and battery manufacturers to test their assemblies in preparation to pass UL 9540A.

“Fike’s goal is to provide ESS design element feedback that will enhance the probability of success during certification testing through a process that is intended to be fast and cost-effective,” said Tom Farrell, Manager of Test and Validation at Fike. “This enables ESS manufacturers to rapidly iterate their design while demonstrating the effectiveness of a custom, performance-based thermal management and fire protection solution.”